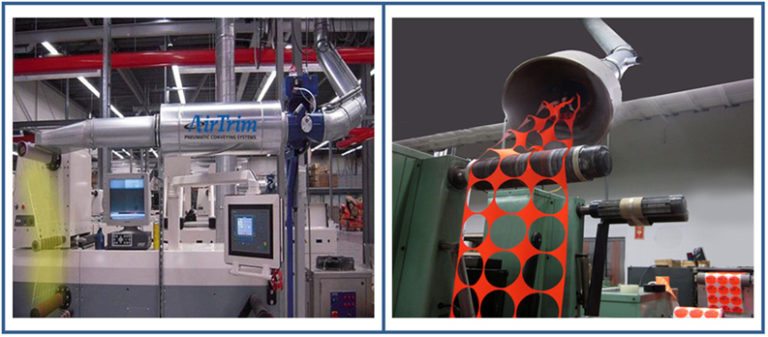

AirTrim engineers and manufacturers proven stationary central pneumatic material handling systems to convey trim, matrix waste and other waste material from converting and printing machines to your desired waste bin of choice. We are unique in that we are the only vendor with the widest amount of experience in the industry specializing in each of the three major system categories: venturi/ inducer, ultra-quiet trim cutter and material handling fan. Most other vendors focus on one of these disciplines; AirTrim has extensive experience in all three. We work with you to determine the best solution that will help you achieve your goals.

Over the years we have designed and perfected many pneumatic material systems that may help your company. The following industry specific applications are a few of our proven, in some cases patented, solutions that will help you achieve higher productivity in your operation.

Communication with our customers is key when engineering a custom central system. To begin the process, please provide us with some initial information on our contact us page. We will contact you to continue the conversation.

Paper, Plastic, Film, Foil Converting

Custom engineered pneumatic waste and dust removal systems incorporating our ultra-quiet trim cutters, patented energy saving adjustable inducers or material handling fans to convey waste trim to a variety of waste receptacle options such as compactors, balers, gaylords and waste carts.

Food

Custom engineered pneumatic system incorporating our patented energy savings adjustable inducer/venturi to convey whole food in stainless steel systems for food processing or convey food waste to a storage area.

Pressure Sensitive Adhesive (PSA) Matrix Removal

Custom engineered pneumatic matrix removal system to convey PSA matrix from a label press to a waste receptacle of choice; allowing for continuous operation and maximum production. Proven designs incorporate either our ultra-quiet trim cutter or patented energy saving adjustable inducer/venturi.

Non-Woven/ Textile

Custom engineered pneumatic waste removal systems conveying waste material such as carpet, floor tiles, vinyl flooring, roof shingles, filters, diaper stock, etc. This system incorporates either our patented energy saving adjustable inducer/venturi or our ultra-quiet trim cutter and conveys the waste to a variety of waste receptacle options such as compactors, balers, gaylords and waste carts.

Paper and Tissue

Custom engineered pneumatic waste and dust removal systems incorporating our ultra-quiet trim cutter, patented energy saving adjustable inducer or material handling fan to convey waste trim to a variety of waste receptacle options such as compactors, balers or gaylord bins.

Flexible Packaging

Custom engineered pneumatic waste and dust removal systems for trim removal applications incorporating our ultra-quiet trim cutter or patented energy saving adjustable inducer/venturi with a variety of waste receptacle options such as compactors, balers, gaylords and waste carts.

High Production Canning

To keep your lid sleeve canning operation clean and organized, AirTrim has designed and proven two helpful systems:

The LST (Lid Sleeve Transport) automatically conveys empty paper lid sleeves from the canning line to the baler area regardless of machine speed.

The Patented ArmPro + LST simplifies the lifting of the lid sleeve and automates the lid sleeve removal process and transporting the paper lid sleeve to the baler area.

Recycling

Proven custom engineered pneumatic system designed specifically for Material Recovery Facilities (MRF’s) to improve efficiency transporting materials from the collection areas to the staging area eliminating the transfer of cans and plastics with carts or vehicles. Our patented energy saving jumbo inducer/venturi can increase production by pneumatically conveying sorted material from the conveyor to the collection bin.

Corrugated

Custom engineered pneumatic waste removal systems integrated with your slitters, flatbed or rotary die cutters for boxes, cartons and food containers to convey waste material from your machine(s) to your waste receptacle incorporating our ultra-quiet trim cutters or patented energy saving adjustable inducers/venturi.